Some popular casting simulation softwares which are available to foundry engineers are AutoCAST, MAGMASoft, ProCAST, SOLIDCast, CAP/WRAFTS, CastCAE, Castflow, Castherm, JSCast, MAVIS, Nova-Solid/Flow, PAM-CAST, RAPID/CAST, and SIMTEC etc.

The present dynamic market demands fast response to customer needs at the right cost and also within stipulated time. No foundry can produce high-quality castings particularly integrated castings without simulation for the first time. For these reasons, casting simulation has become an indispensable tool in modern foundries.

#Methoding magmasoft software#

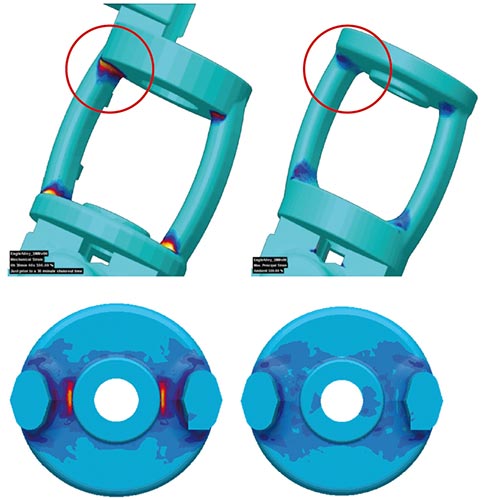

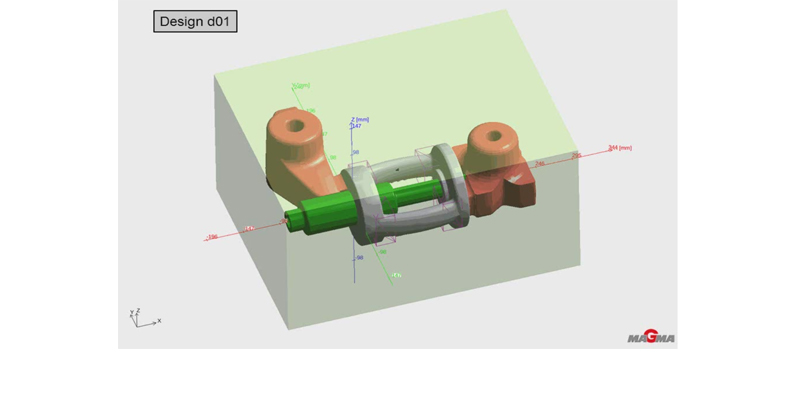

The simulation software can be used for the development of any new castings or it can be used for standardize any existing casting for any design change to improve yield of the casting without shop floor trial. It can also pin point the position of internal defects like shrinkage porosity, sand inclusions and cold shuts etc. Now a days, these modeling methodologies are so strong that they can accurately predict the microstructure and mechanical properties of the castings. It is ubiquitous that a set of governing equations are required to model these phenomenon in a computer program. The casting simulation software producing farms always keep target to accurately simulate the physical phenomena as far as possible like the mould filling, associated heat-transfer, solidification pattern of the metal/alloy, and the involved phase transformation of castings. Geometry, material, and process are three major influencing factors related to metal casting. Several researchers have worked hard for several decades to find out the same.

Therefore, the key to develop a practical useful casting simulation software is to figure out the related most important parameters. Actually, metal casting is a process which has numerous associated controlling factors. It is often said that the development of accurate simulation software is a ‘rocket science for rocket scientists’. Naturally, metal casting simulation is a very complex phenomenon which involves flow of fluid, heat transfer between mould and molten metal etc. Metal casting is a manufacturing process where molten metal is poured into a mould cavity of required shape and size and allowed to solidify. Simulation imitates a real phenomenon by the use of certain mathematical equations. In this chapter some of the live examples have been cited to understand the process logically and scientifically. This chapter illustrates the advantages of casting simulation (both tangible and intangible), bottlenecks (technical and resource-related), and some best practices to subdue the bottlenecks. It can be adopted for troubleshooting existing castings, and for producing new castings without or minimum shop-floor trials.

Simulation software can be very helpful in calculating tedious formulas, constructing solid modeling which will be helpful to visualise the actual situation like core/mould assembly, gating and feeding arrangements with the main casting before going into actual practice. The application of simulation software enables us to say, “Get it right, the first time and every time”. Casting simulation software simulates the way how casting engineers decide the casting process in a virtual platform and also analyzes each decision to point out the design modifications needed to enhance the quality of casting as well as reduce lead time, tooling and manufacturing costs. But still, defects and rejection of castings are ubiquitous because in general, the designer lacks domain knowledge about casting processes and hardly have any methodology to find out the parameters that produce sound casting. Production of sound casting demands a thorough understanding of whole casting process.

0 kommentar(er)

0 kommentar(er)